![]()

BORTOM KUNDENS FÖRVÄNTNINGAR:

FÖRBÄTTRAD KVALITET OCH ENERGI SPARANDE

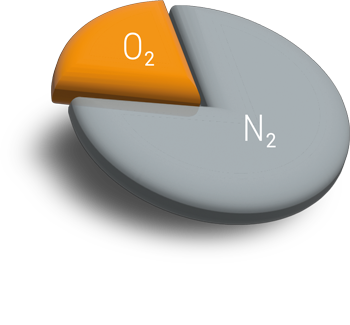

En traditionell brandpoleringsprocess bygger på sammanslagning av gaser som naturgas, metan eller propan med tryckluft och elda upp denna blandning till rätt antändningstemperatur. Denna process medför en hög nivå av energiavfall: Kväve ur tryckluft måste värmas upp!

En annan viktig energirelevant fråga är det kontinuerliga flödet av artiklar, passerar genom en tunnel med permanent drivna brännare på båda sidor. Lågor riktas alltså inte bara mot föremålets ytor utan de förbränner också en stor mängd värdefull energi för utrymmen mellan glasartiklarna. This leads to an unnecessary and expensive loss of energy.

En annan viktig energirelevant fråga är det kontinuerliga flödet av artiklar, passerar genom en tunnel med permanent drivna brännare på båda sidor. Lågor riktas alltså inte bara mot föremålets ytor utan de förbränner också en stor mängd värdefull energi för utrymmen mellan glasartiklarna. This leads to an unnecessary and expensive loss of energy.

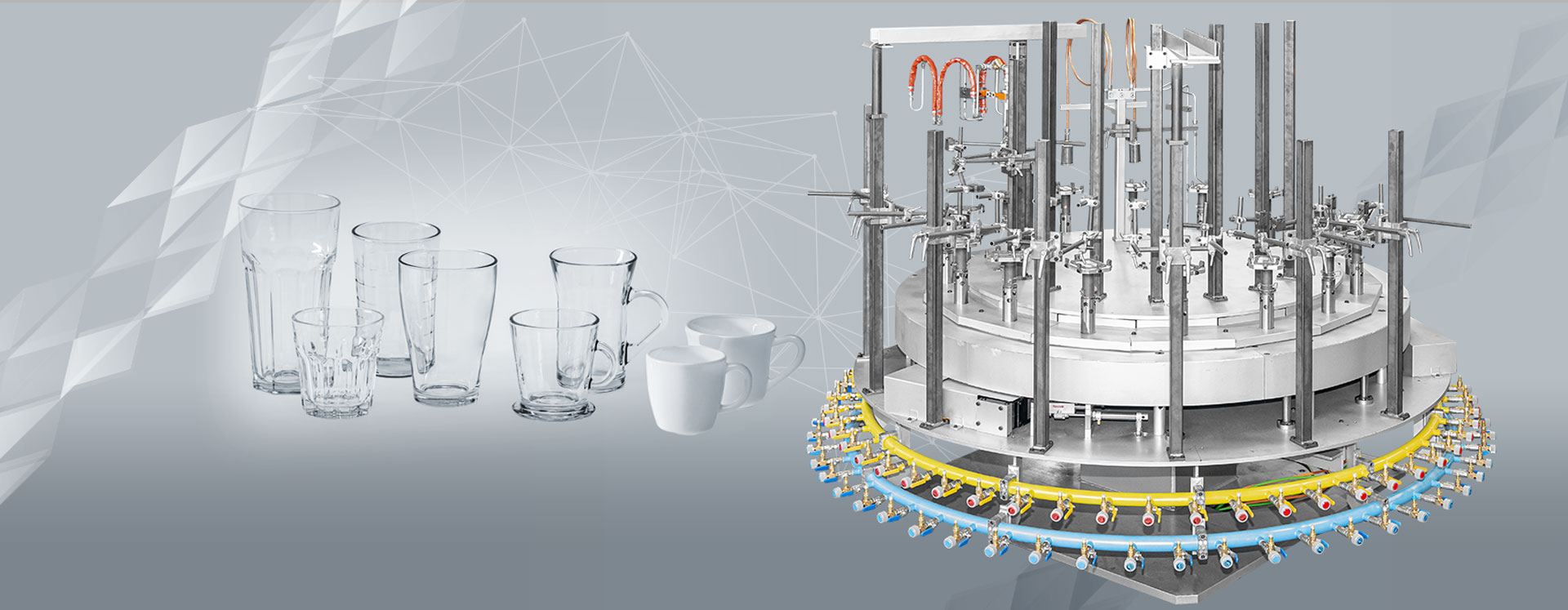

WALTECs servodrivna brandpoleringslinjer med innovativ spårningsbrännarteknik driver energibesparingar, förbättra produktkvaliteten och stödja multiproduktfunktionalitet.

WALTEC ersatt tryckluft med syre – sparar ca 30% av förbränningsgaser. The innovative burner tracking system decreases the gas consumption by another 50%.

WALTEC‘s state of the art servo-powered fire polishers with gas and oxygen as well as the tracking burner technology feature comprehensive energy savings up to 80%.

Servo drive technology fully synchronizes the article transport and spindle rotation with the tracking burners and guarantees high precision energy-efficient polishing and the best possible surface quality.

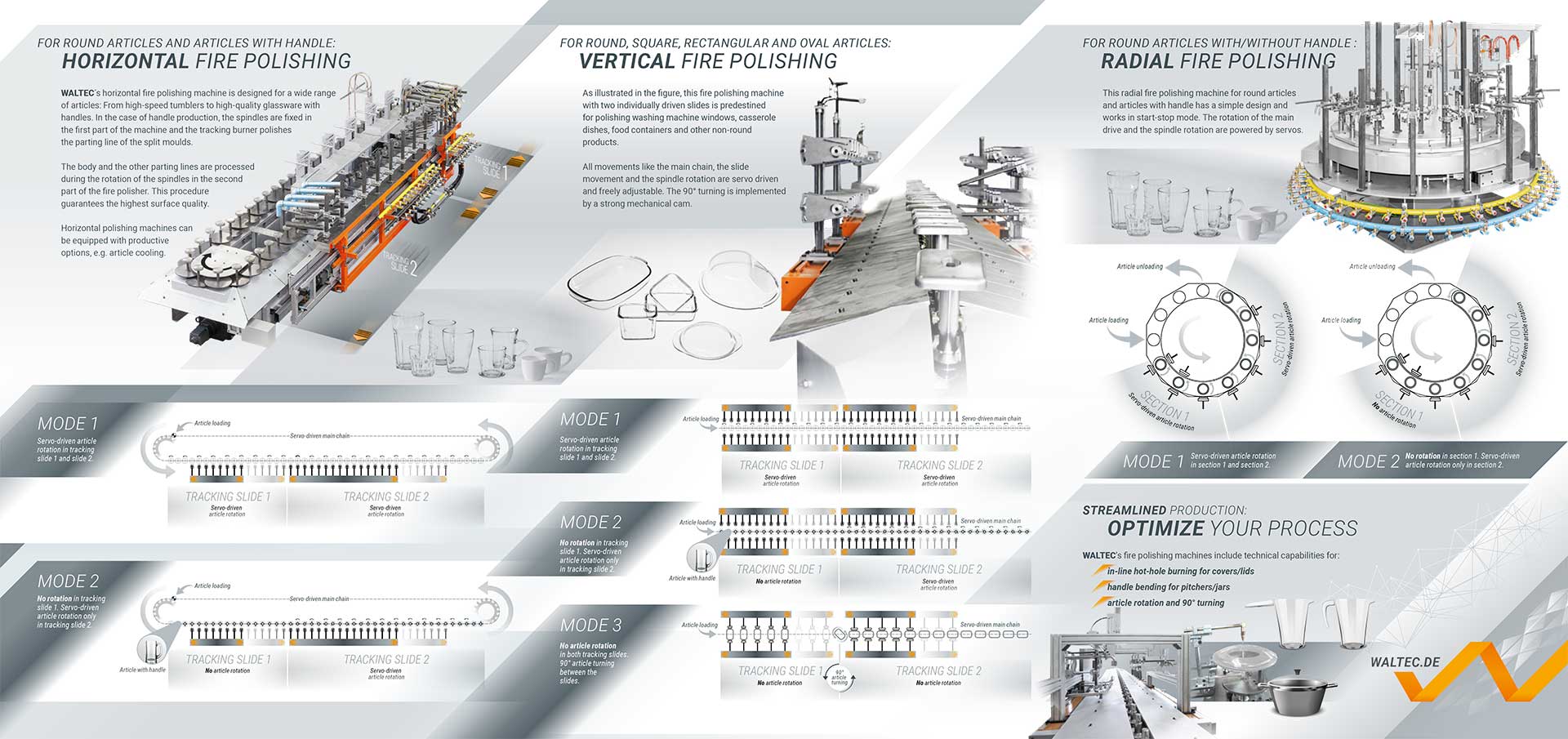

FOR ROUND ARTICLES AND ARTICLES WITH HANDLE:

HORIZONTAL BRANDPOLERING

WALTEC´s horizontal fire polishing machine is designed for a wide range of articles: From high-speed tumblers to high-quality glassware with handles. In the case of handle production, the spindles are fixed in the first part of the machine and the tracking burner polishes the parting line of the split moulds.

The body and the other parting lines are processed during the rotation of the spindles in the second part of the fire polisher. This procedure guarantees the highest surface quality.

Horizontal polishing machines can be equipped with productive options, t.ex. article cooling.

MODE 1

Servo-driven article rotation in tracking slide 1 och glida 2.

MODE 2

No rotation in tracking slide 1. Servo-driven article rotation only in tracking slide 2.

FOR ROUND, SQUARE, RECTANGULAR AND OVAL ARTICLES:

VERTICAL BRANDPOLERING

As illustrated in the figure, this fire polishing machine with two individually driven slides is predestined for polishing washing machine windows, casserole dishes, food containers and other non-round products.

Alla rörelser som huvudkedjan, the slide movement and the spindle rotation are servo driven and freely adjustable. The 90° turning is implemented by a strong mechanical cam.

MODE 1

Servo-driven article rotation in tracking slide 1 och glida 2.

MODE 2

No rotation in tracking slide 1. Servo-driven article rotation only in tracking slide 2.

MODE 3

No article rotation in both tracking slides. 90° article turning between the slides.

FOR ROUND ARTICLES WITH/WITHOUT HANDLE:

RADIAL BRANDPOLERING

This radial fire polishing machine for round articles and articles with handle has a simple design and works in start-stop mode. The rotation of the main drive and the spindle rotation are powered by servos.

MODE 1

Servo-driven article rotation in section 1 and section 2.

MODE 2

No rotation in section 1. Servo-driven article rotation only in section 2.

STREAMLINED PRODUCTION:

OPTIMERA YOUR PROCESS

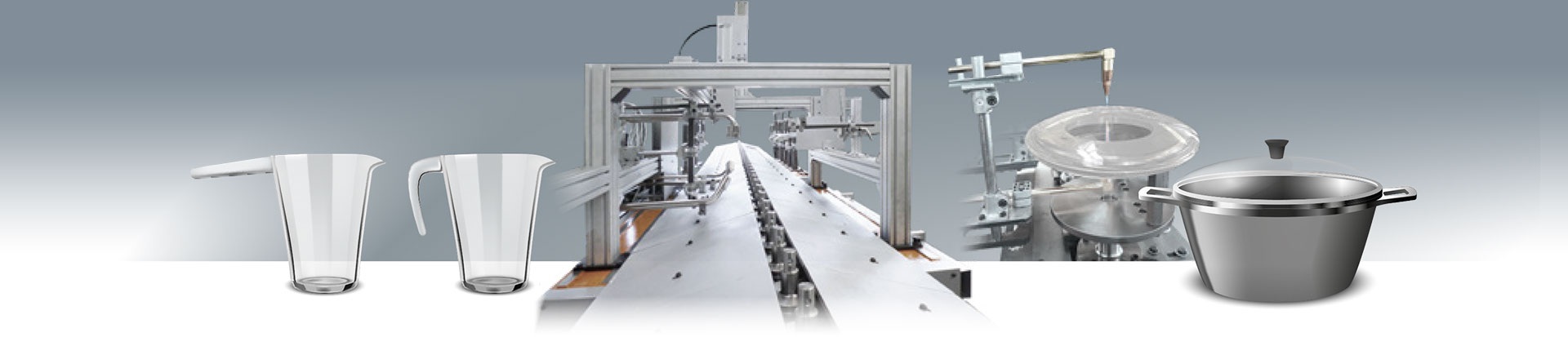

WALTEC’s fire polishing machines include technical capabilities for:

In-line hot-hole burning

for covers/lids

Handle bending

for pitchers/jars

Article rotation

and 90° turning

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)