![]()

Speed up to 240 cycles per minute!

Flexibility, high speed, positioning accuracy, vacuum system, gripper system – these are the main demands which are placed by our customers on the handling and transfer systems. Optimum handling and transfer systems can be planned for all glass articles through a suitable combination on the basis of WALTEC standard systems due to the modular design.

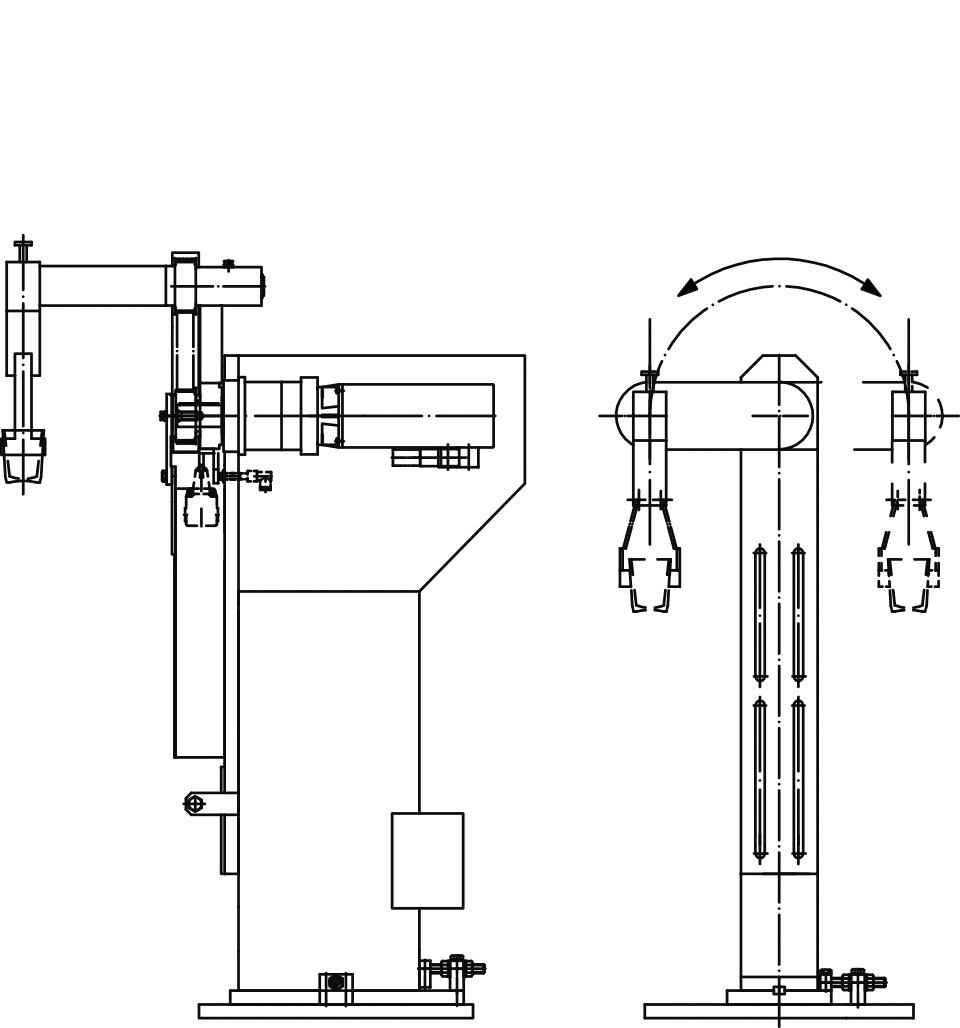

take-out for heavy-weight articles

The HVM take-out is designed for maximum production speeds and maximum flexibility. Two suction head or gripping arms rotate around a vertical axis. The vertical stroke of the arms is variable in the pick-up and place positions. Due to this, no height adjustment of the take-out and/or polishing machine is necessary for different mould and article heights. The rotary and stroke movements have been realised with electrical servo- axes and the speeds adjust automatically in case of production speed changes.

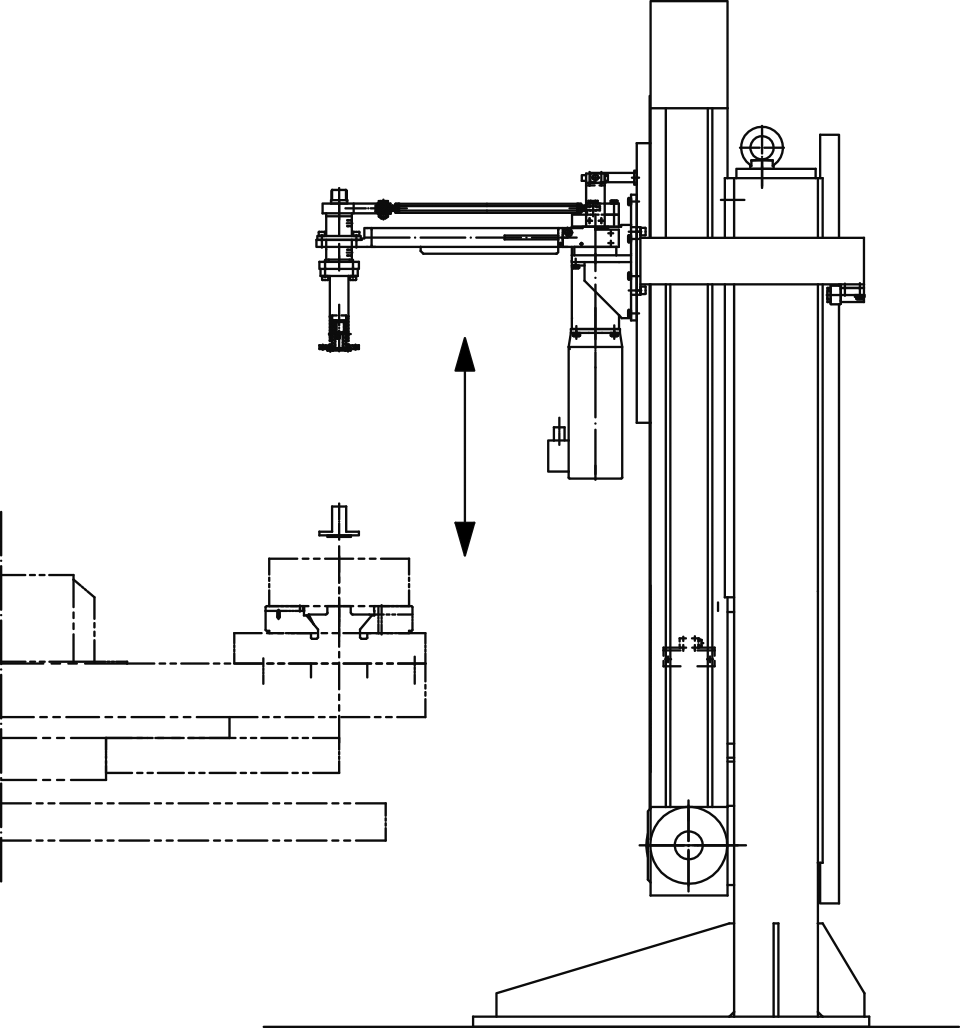

The HDE take-out with electrical servo-axes has been designed for large vertical and horizontal distances with gripper or vacuum take-out.

The HSE take-out, with only one servo-drive for vertical and horizontal movement, has been developed for gripper or vacuum take-out.

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)